Industrial Sensor part 7 ( Eng Audio )- Photoelectric Sensor Types and Application a quick overview

- Get link

- X

- Other Apps

This video tutorial is about to have a overview about all Basic photoelectric sensor as below:-

- Diffuse/ proximity Sensor - Miniature , Fiber optic & laser sensor.

- Retroreflective Sensor - Miniature , Fiber optic & laser sensor.

- Thru Beam Sensor - Miniature , Fiber optic & laser sensor.

- Eye mark or color mark sensor.

- Color sensor.

- Luminescence / UV Sensor.

- Safety Curtain sensor

Click Below link for Video tutorial:-

Explanation:-

We would be having a quick review for Photoelectric sensor Types and application

we would be covering below Basic Photoelectric sensors:-

- Diffuse/ proximity Sensor - Miniature , Fiber optic & laser sensor.

- Retroreflective Sensor - Miniature , Fiber optic & laser sensor.

- Thru Beam Sensor - Miniature , Fiber optic & laser sensor.

- Eye mark or color mark sensor.

- Color sensor.

- Luminescence / UV Sensor.

- Safety Curtain sensor

Photoelectric Sensor uses Light for detection of Objects. red light is most widely used, other than red light blue, green light are also used.

Red light are mostly used because they cannot be tampered by any other light easily.

Light reflected/Diffused from object is received at receiver due to which sensor detects object. They are most widely used for high speed application in machine packaging / filling or processing line. they are used in pharma, beverages, Material handling and Automobile industry.

1. Diffuse / proximity Photoelectric Sensor

There are 3 basic types in diffuse types

- Miniature

- Fiber optic

- Laser

Diffuse sensor can be used for below applications:-

2. Retroreflective Photoelectric sensor

There are 3 basic types in Retro reflective types

- Miniature

- Fiber optic

- Laser

Retroreflective sensor has more accuracy than diffuse sensor, as reflector is been used. If any object is coming between reflector and sensor object is detected.

Retroreflective sensor can be used for below applications:-

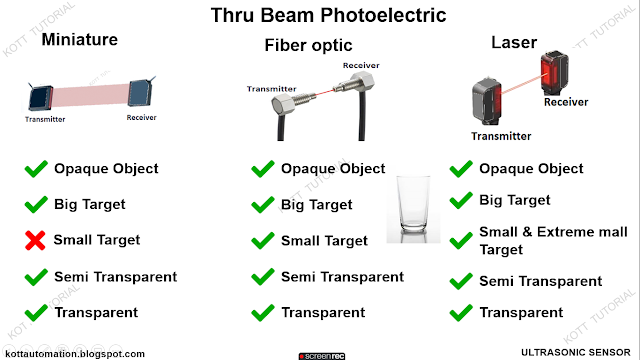

3. Thru beam sensor

Thru beam sensor has separate Transmitter & receiver. If any object is coming between Trans & receiver the object would be detected.

Thru beam sensor has more accuracy than Diffuse or retroreflective sensor

There are 3 basic types in diffuse types

- Miniature

- Fiber optic

- Laser

4. Eye Mark / Color mark / Contrast Sensor

Mark sensor are used for detection of mark / registration mark. They can only differentiate between 2 colors and generate output.

5. Color sensor

Color sensor can detect all different color objects in VIBGYOR and generate individual output.

They are also called as color RGB sensor. Used for registration mark and Color sorting machine.

6. Luminescence / UV sensor

This sensor are specifically used for detection of luminescent objects or mark. They are used for hologram or UV coated labels. They can also be used to detect carton shiny tamper labels.

7. Safety curtain sensor

Safety curtain sensor is used to safeguard operator in hazardous machining environment. They are designed for safety purposes. they consist of array of sensor light. If any light is been blocked sensor generate output signal.

They are also used for object Height and Width measurement.

Thanks

KOTT TUTORIAL

Rohit K

- Get link

- X

- Other Apps

Comments

Hello, I have problèm with PLC B&R 2005 IF260, Can you give me the software of this PLC

ReplyDelete